What happens inside a typical Hammond organ is quite interesting, and also it was quite a novel concept regarding producing sounds from a musical instrument when it first appeared. The actual sounds that you hear from a Hammond organ come from fairly conventional loudspeakers. Prior to reaching the speakers, the musical signals in the Hammond are electrical. Actually they are alternating currents, one each for every note that the instrument can produce. In fact, in some ways, the Hammond system is a little bit like a really tiny power station, producing minute alternating currents of all of the frequencies that a typical organ would need. Furthermore, the Hammond system would never go out of tune, and is impervious to outside influences like temperature, humidity, and barometric pressure, all of which can affect the tuning of conventional musical instruments.

Figure 1. Typical tonewheel showing complete circuit including output filtering transformer and capacitor, and also the output AC signal.

The secret of the Hammond organ is the tonewheel, and because a typical Hammond organ produces 91 different pitches, there are 91 tonewheels in the instrument. Each tonewheel is a small steel disc about 2" in diameter, and around its circumference there are a number of small lobes that are somewhat like gear teeth. Each tonewheel rotates at a constant speed, and close to the edge of each tonewheel there is a pencil-like permanent magnet. On each magnet, Hammond placed a coil of magnet wire, and when the wheel spins, the action of these lobes influences the magnetic field of the permanent magnet. This field influencing induces a tiny alternating current in the coil, and the frequency of this AC represents one pitch of a standard musical keyboard. The frequency of this AC depends on how many teeth or lobes pass by the magnet in one second. Therefore, the output frequency depends on both the number of lobes on the tonewheel, and also how many revolutions per minute it makes.

For instance, if a certain tonewheel has 16 lobes, and if this tonewheel likewise spins at 1650 RPM, then that means that 26,400 lobes will pass the end of the magnet every minute. Dividing this by 60 seconds per minute, we find that 440 lobes pass the magnet in one second. Therefore, the frequency of the AC that is generated in the coil on this magnet will be 440 Hz, or the note A440 on a standard musical scale. And A440 is the universally agreed-upon standard for Middle A on all correctly tuned pianos, organs, electronic keyboards, and is also the pitch to which orchestral instruments normally will tune, because obviously, in order to have a musical group like a band or an orchestra, everybody's instruments will have to be tuned alike to a standard if they are supposed to play together.

Here in figure one is a simple animated diagram of a 16 lobe tonewheel in a Hammond organ. Obviously the motion in this drawing is greatly slowed down, but it illustrates the basic principle. At 1650 RPM, the wheel would be turning so fast that the lobes would appear blurred like the blades of an electric fan.

In an actual Hammond tone generator, various groups of tonewheels spin at twelve different speeds, 1650 RPM is just one of these twelve rotational rates. Also, tonewheels of varying types have respectively 2, 4, 8, 16, 32, 64, 128, and 192 lobes. Because various octaves of any particular note of a musical scale have frequencies that are in a 2:1 ratio, most groups of Hammond tonewheels likewise have lobing that is in a 2:1 ratio as well. However, the top seven highest frequencies that a Hammond organ has come from tonewheels which have lobing that is 1.5:1 times the next lower pitched group of tonewheels, and 192 = (1.5)(128). If you are mathematically inclined, then you will find the math involved with musical scaling and temperaments very interesting, but that is beyond the scope of this article. Click here to learn more.

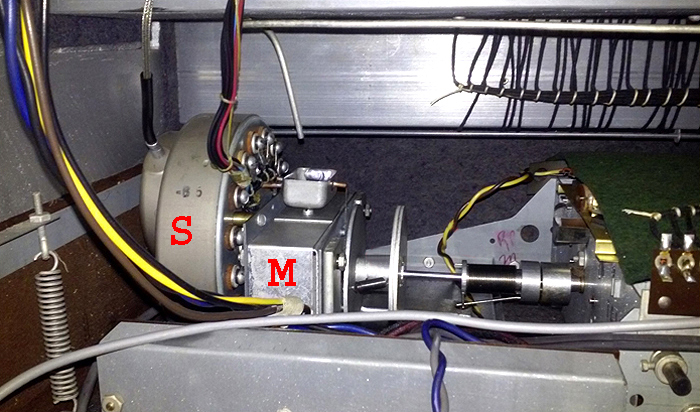

Figure 2. This picture shows a Hammond synchronous motor (red "M") and also the attached vibrato scanner (red "S") in a typical Hammond B3, although these parts are identical in C3s, and all other standard, traditional Hammonds. It also shows the flywheels and spring couplings that are there to smooth out the rotation and eliminate any 60 and 120 Hz mechanical vibration that might otherwise be present in the drive shaft from the motor.

In a Hammond tone generator, all of the various tonewheels are powered through gears from a common shaft which turns at exactly 1200 RPM. The gear ratios are designed to produce twelve different speeds which correspond very accurately to the frequencies of the twelve tones of a modern equally tempered scale, that is, the tone wheel speeds correspond to the frequencies of C, C♯, D, D♯, E, F, F♯, G, G♯, A, A♯, and B. The common shaft is powered by a 1200 RPM synchronous motor. Synchronous motors run in exact step with the frequency of the AC power that supplies them. In a Hammond organ, the synchronous motor makes one complete revolution for every three cycles of the AC power, so on standard 60 cycle power, that means twenty revolutions per second. In the USA, utility-supplied 60 Hz AC is very accurately controlled, so we may consider the 60 Hz of the AC power that we all use as being a constant and a standard. Therefore, any musical instrument that depends on utility supplied 60 Hz power will have constant accurate tuning. Here, figure 2, is a look at a Hammond organ synchronous motor in a B3 Hammond organ.

This type of motor tends to run in a series of pulsations which would normally result in 120 hz mechanical vibration in its output which could carry into the gearing and the tonewheels. In order to eliminate this, there are several flywheels that are coupled to the motor via coil springs, and then the output shaft of the motor drives the main tone generator shaft through a large helical spring. This mechanical filtering eliminates all 120 Hz mechanical vibration and assures that the tone wheel drive shaft will run absolutely smoothly at its design speed of 1200 RPM.

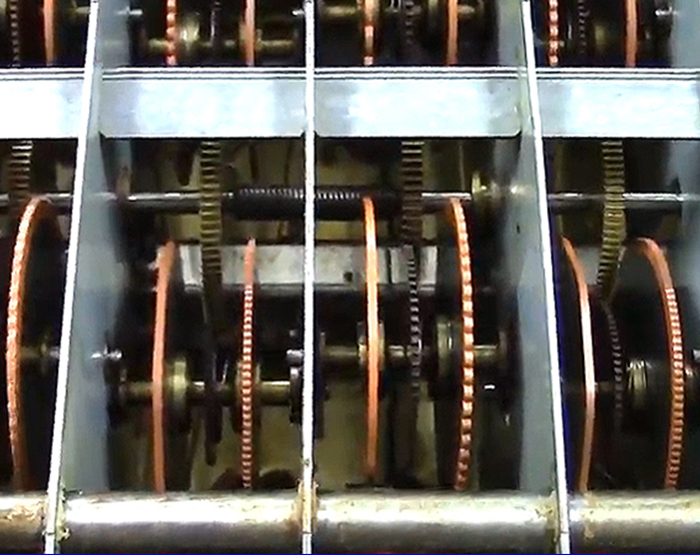

Figure 3. Here, figure 3, is a look at a portion of a Hammond tone generating unit. This shows the arrangement where several pairs of tonewheels are driven from the main shaft. Unfortunately, this picture does not show any of the small permanent magnets and their pickup coils, but it is a good general view of how the tonewheels are arranged. Two tonewheels are mounted in pairs on a common shaft.

A single pair of gears drives each tonewheel pair, gears are designed to give the correct RPMs so that the tonewheels in each pair of compartments all run at the same speed and produce different octaves of the same note, depending on how many lobes each tonewheel has. Notice that in the center of the picture, you see a helical spring connecting two end-to-end sections of the main shaft. Also, although hard to see in this picture, there is a helical spring between the gears on the tonewheel shaft and one of the tonewheels. This is to eliminate any gear tooth ripple frequencies from affecting the absolutely smooth rotation of each tonewheel pair.

All of these various spring couplings on the main shaft and at each tonewheel pair help to eliminate any extraneous mechanical vibrations that might otherwise develop in the tone wheel system, and this shows also what an excellent example of good mechanical design a Hammond tone wheel generator is.

There are 91 tonewheels in a typical standard Hammond organ. This results in a pitch range of 7 equally tempered octaves of 12 pitches. At the top end of the instrument there are an additional 7 pitches, making the total frequency range of the Hammond one note greater than 7.5 octaves. Figure three shows a portion of a Hammond tone generator, looking in from below where we can see the actual tonewheels and also the driving gears that transmit the power from the main shaft. These gears are very carefully designed and their tooth ratios are carefully calculated so that the speeds of the tonewheels are correct for the number of lobes on each one to generate a very accurate equally tempered musical series of pitches. Although a truly accurate equally tempered scale exists only in theory, and all of the frequencies other than various octaves of the pitch A are actually never-ending decimals, the Hammond gear system gives a very accurate approximation, with pitch errors that are so small that they can only be measured by sophisticated electronic instrumentation. The tuning of a Hammond organ is more accurate than that which a very experienced piano tuner could get on a fine Steinway piano even if he spent a whole day on the job. Thus, the Hammond can serve as an accurate tuning standard and can be used to establish a base line pitch reference for any other musical instruments that are tunable. A standard Hammond organ is not tunable, and has no tuning adjustments.

From these tonewheel generators, the various AC frequencies are conveyed through lengths of resistance wire to the nine contacts that are placed under every playing key. Each key on a typical Hammond can sound up to nine harmonically related pitches. The way that a Hammond makes many different tone colors is by mixing different portions of these harmonically related frequencies together, and the musician controls this by means of sliding volume controllers called harmonic drawbars. Each drawbar can be in one of nine positions. The first position represents zero, or no volume at all. The remaining 8 positions all represent increases in signal strength. By choosing what harmonics are present and also the relative intensity of each, the musician can make the instrument create a huge number of various combinations and thus create a large number of different tonalities, some of which imitate (with varying degrees of accuracy) other musical instruments, and some combinations represent sounds that are specific to the Hammond organ. If you have 9 harmonic controllers, and each can be in one of 9 positions or settings, then you have nine to the ninth power or 387,420,489 different possible combinations. In actuality, many combinations can sound exactly alike, but at different pitches or volume levels, or so close that they appear to be the same. Realistically, there are still at least 700 to 6500 significantly different possible tonalities; (depending on how you calculate and how much of a difference you accept as being significant) each of which has many slightly different variations, so this makes the Hammond one of the most tonally versatile instruments ever created.

After these signals are mixed into various sounds, they next go through an input preamplifier, a volume control, a second or output stage of the preamplifier, and finally to a power amplifier which raises the signal strength to that needed to power speakers where they become audible music.

Associated with the preamplifier is special circuitry to provide a pitch-varying vibrato that can be applied to the musical signals from either or both keyboards, and also a special percussion effect which simulates the effect of a bell or tuned bar where the signal begins loudly and gradually fades in volume as you hold down one or more playing keys. If you let go of the playing keys, the signal stops entirely, so in effect it behaves like a piano with dampers that are instantaneous and also 100% efficient.

Of necessity, the preceding description is greatly simplified, and in an actual Hammond instrument, what actually takes place is technically far more complicated and detailed. If you are curious to find out in detail what actually happens in a typical standard hammond organ, go here for a comprehensive and detailed look inside a Hammond organ. Back to Main Street Music USA Hammond page.